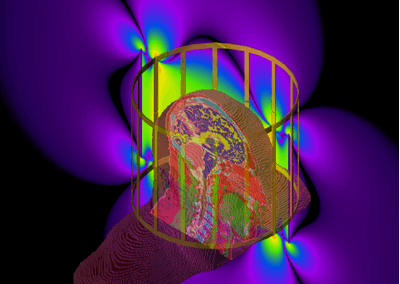

This will allow our users to shorten their design cycle and get their product to the market quickly.ĮMS targets four main areas: electromechanical, electromagnetics, power electronics, and electromagnetic behavior.ĮMS empowers the designer to compute electric, magnetic, mechanical, and thermal parameters - including, force, torque, magnetic flux density, magnetic field, electric field, electric flux, current flow, eddy current, inductance, capacitance, resistance, flux linkage, core loss, saturation, induced voltage, force density, power loss, temperature, temperature gradient, heat flux and more.ĮMS applications include: motors, generators, linear and rotational actuators, relays, MEMS, magnetic recording heads, magnetic levitation, solenoids, loud speakers, coils, permanent magnets, sensors, NDT, NDE, high power, high voltage, transformers, inverters, converters, bus bars, inductors, insulation studies, bushings, electrostatic discharge, electromagnetic shielding, EMI, EMC, medical devices, eddy current devices, fuses, circuit breakers, capacitors, etc. It provides accurate results and is highly customizable. The full integration in Inventor means that users will not need to import, export, heal, clean, or fix any geometrical inconsistency because they will be working right inside Inventor while optimizing their electromechanical design. ANSYS Maxwell is a high-performance electromagnetic field simulation software package specifically designed for electric machine design. Magma engineering team can accurately represent the complex geometry of the magnetic fields.

EMS is a 3D electromagnetic field simulator software suite, based on the powerful finite element method.ĮMS is seamlessly integrated inside Autodesk® Inventor®. Magma uses Ansys Maxwell software for magnetic FEA analysis.

0 kommentar(er)

0 kommentar(er)